A Comprehensive Guide to Setting Up Your Jewelry Casting Studio: From Concept to Creation

Embarking on the journey of creating your own jewelry from scratch is a deeply rewarding experience, and for many, that path leads to the art of casting. Casting allows you to transform your intricate designs, whether hand-carved in wax or digitally modeled, into beautiful, enduring pieces of metal. Setting up a dedicated casting studio, however, requires careful planning, knowledge of the necessary equipment, and a strong commitment to safety.

This extensive guide will walk you through everything you need to know to establish your own jewelry casting studio. We’ll cover the essential equipment, from fundamental tools to specialized machinery, and provide an overview of the process. We will also delve into the critical aspects of studio setup, including workspace design and safety protocols. Finally, for those in Australia, we’ve included a curated list of gem and lapidary clubs that offer invaluable classes and a supportive community for aspiring jewelers.

The Foundation: Understanding the Casting Process

Before you start filling your cart with equipment, it’s crucial to understand the “lost wax” casting process, which is the most common method for fine jewelry.

- Wax Model Creation: Your journey begins with a detailed wax model of your design. This can be sculpted by hand using wax carving tools or created with a 3D printer using a special castable resin.

- Spruing: The wax model is attached to a wax “sprue” or tree, which acts as a channel for the molten metal to flow into the mold. Multiple models can be attached to a single tree for efficiency.

- Investing: The wax tree is placed inside a metal flask. A plaster-like material called “investment” is mixed with water and poured into the flask, encasing the wax models. This slurry is then vacuumed to remove air bubbles, ensuring a smooth, flawless mold.

- Burnout: The flask is placed in a high-temperature kiln or burnout furnace. Over several hours, the temperature is gradually raised to melt and vaporize the wax, leaving a perfect, hollow cavity in the investment.

- Casting: The pre-heated flask is removed from the furnace and placed in the casting machine. Molten metal (gold, silver, platinum, etc.) is then poured or injected into the mold.

- Quenching and Cleanup: After the metal has solidified and cooled slightly, the flask is submerged in a bucket of water. This rapid cooling process shatters the investment, revealing the raw metal casting.

- Finishing: The cast piece is then cleaned, polished, and detailed to perfection. This includes cutting the sprues, filing, sanding, and polishing to achieve the desired finish.

Now that you have a grasp of the process, let’s explore the essential equipment required for each step.

Essential Equipment for Your Jewelry Casting Studio

Setting up a studio can range from a minimalist, small-batch operation to a full-scale, professional setup. Here is a comprehensive list of equipment, broken down into categories for a clear understanding of what you’ll need.

Workspace and Safety Essentials

A safe and organized workspace is non-negotiable. This is your foundation.

- Jeweler’s Workbench: A sturdy, purpose-built jeweler’s bench is ideal. It features a “bench pin” for holding and working on pieces, and a catch tray to collect metal filings. A solid wooden desk can be a budget-friendly alternative.

- Proper Lighting: Good lighting is crucial for intricate work. An adjustable task lamp with a bright, neutral light source will reduce eye strain.

- Ventilation System: This is arguably the most important safety investment. Casting, melting metal, and polishing create fumes and dust that are hazardous to your health. A proper ventilation hood or a downdraft table is essential. At a minimum, a fan that exhausts air directly outside is a must.

- Personal Protective Equipment (PPE):

- Safety Goggles or Face Shield: Protect your eyes from heat, splashes, and flying debris.

- Heat-Resistant Gloves: Crucial for handling hot flasks and crucibles.

- Respirator Mask: A respirator with a particulate filter is necessary to protect against inhaling investment dust and metal fumes. An N95 mask is a bare minimum for dust.

- Leather Apron: Protects your clothing and body from heat and spills.

- Closed-Toe Shoes: A simple but vital detail to protect your feet from dropped tools or hot metal.

- Fire Extinguisher: A class D fire extinguisher is specifically designed for metal fires and should be easily accessible. A general-purpose extinguisher is also a good idea.

Wax Working and Model Creation

This is where your designs take shape.

- Wax Carving Tools: A set of wax files, carving knives, and spatulas are used to sculpt models from blocks of carving wax.

- Wax Injector: For replicating designs from a master mold, a wax injector melts and injects liquid wax into a rubber or silicone mold.

- Wax Pen or Electric Waxer: This tool is like a miniature soldering iron for wax, allowing for precise additions and repairs to your models and sprues.

- 3D Printer (Optional): As technology advances, 3D printers that use a castable resin are becoming more popular. This allows you to create highly detailed and complex designs digitally.

Investment and Mold Preparation

This phase creates the “negative” space that your metal will fill.

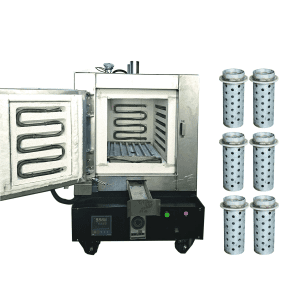

- Flasks: These are the metal cylinders that hold the wax model and investment. They come in various sizes.

- Sprue Bases: A rubber base that seals the bottom of the flask and holds the wax tree upright.

- Vacuum Mixer: This machine is a game-changer. It mixes the investment powder and water in a vacuum, pulling out all the air bubbles to ensure a flawless mold without surface defects. A basic mixing bowl and whisk can work for small flasks, but the results may be less consistent.

- Digital Scale: Precision is key when mixing investment. A gram-scale with a high degree of accuracy is essential to get the correct water-to-powder ratio.

- Distilled Water: Using distilled water instead of tap water prevents contaminants from interfering with the chemical reaction of the investment.

Melting and Casting

This is the core of the casting process, where the magic happens.

- Burnout Furnace/Kiln: This is a specialized oven that heats the flask to extremely high temperatures, burning out the wax and preparing the mold for casting. A programmable kiln is highly recommended for precise temperature control.

- Melting Furnace or Torch: You need a way to melt your metal.

- Electric Melting Furnace: Ideal for melting larger quantities of metal. They offer precise temperature control.

- Oxygen/Propane or Oxygen/Acetylene Torch: Suitable for melting smaller batches of metal in a crucible. A “rosebud” tip is recommended for its large, hot flame.

- Crucible: A small, heat-resistant dish made of ceramic or graphite used to hold and melt the metal.

- Casting Machine: This machine uses centrifugal force, vacuum, or induction to push the molten metal into the investment mold, ensuring it fills every detail. For a beginner, a small, manually operated centrifugal casting machine is a great starting point.

Finishing and Polishing

The final steps to bring your piece to life.

- Flex Shaft or Rotary Tool: A versatile tool with various attachments for grinding, drilling, sanding, and polishing.

- Jeweler’s Files: A set of files in different shapes and sizes for refining the metal surface.

- Abrasive Tools: Sandpaper, rubber wheels, and other abrasives for smoothing and shaping the casting.

- Polishing Machine or Tumbler: A bench-top polishing motor with various buffs and compounds will give your jewelry a high-shine finish. A rotary tumbler with steel shot can also be used to burnish and harden the metal.

- Pickle Pot: A small pot that heats a mild acid solution (pickle) used to clean the firescale (oxidation) off your casting.

Gem Clubs in Australia That Teach Jewelry Making

While setting up a home studio is the ultimate goal, learning from experienced professionals is invaluable. Gem and lapidary clubs are a fantastic resource, offering classes, shared studio space, and a community of like-minded individuals. They can provide a hands-on introduction to a range of skills, including casting. Here are some notable clubs and organizations across Australia:

- Nunawading and District Lapidary Club (Victoria): Located in Nunawading, this club offers a variety of training courses in lapidary, silversmithing, and jewelry making. They provide access to well-equipped club rooms and are an excellent resource for beginners.

- Essendon Gem & Lapidary Club Inc. (Victoria): Founded in 1969, this family-friendly club has a purpose-built workshop with facilities for faceting, cabochon work, silverwork, and jewelry making.

- Townsville Gem and Mineral Club (Queensland): Townsville’s only club for jewelry making, lapidary, and “Art Metal” which includes casting, enameling, and silversmithing. They hold regular educational workshops and have a team of experienced instructors.

- Lapidary Club of NSW (New South Wales): Established in 1953, this is one of the oldest clubs in Australia. Based in Surry Hills, they have a long history of teaching and promoting lapidary arts and jewelry making, with well-equipped workshop facilities.

- Gem & Lapidary Council of NSW: This organization provides a directory of numerous gem and lapidary clubs throughout New South Wales. Clubs like the Blaxland Gem and Mineral Club, Blue Mountains Lapidary Club, and others offer classes in jewelry making and silversmithing.

- JamFactory (South Australia): While not a traditional “club,” JamFactory in Adelaide is a renowned center for craft and design that offers short courses and workshops in jewelry making, including lost wax casting.

- Melbourne Polytechnic (Victoria): For those seeking a more formal education, Melbourne Polytechnic offers a range of courses from short introductory classes to a full Certificate III in Jewellery Manufacture, which includes extensive training in various techniques.

By combining the knowledge of proper studio setup and safety with the hands-on experience and community support offered by these Australian clubs, you can confidently and safely begin your journey into the captivating world of jewelry casting

Our blog has a great deal of further details

Jewellery casting equipment, tools supplies. Lowest prices in Australia.