Description

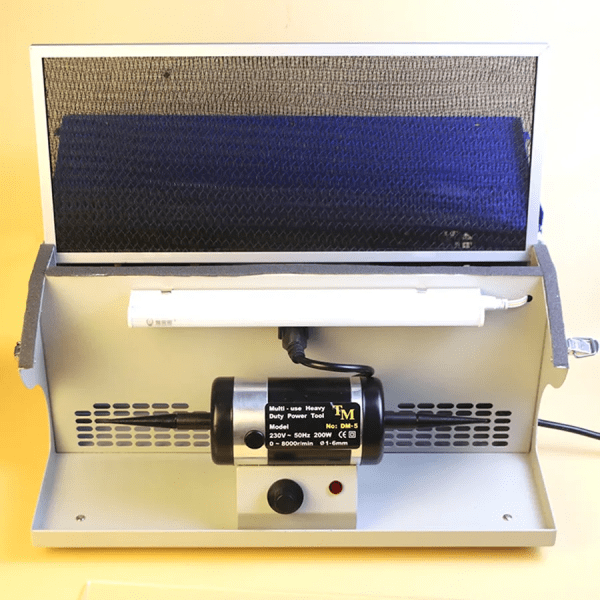

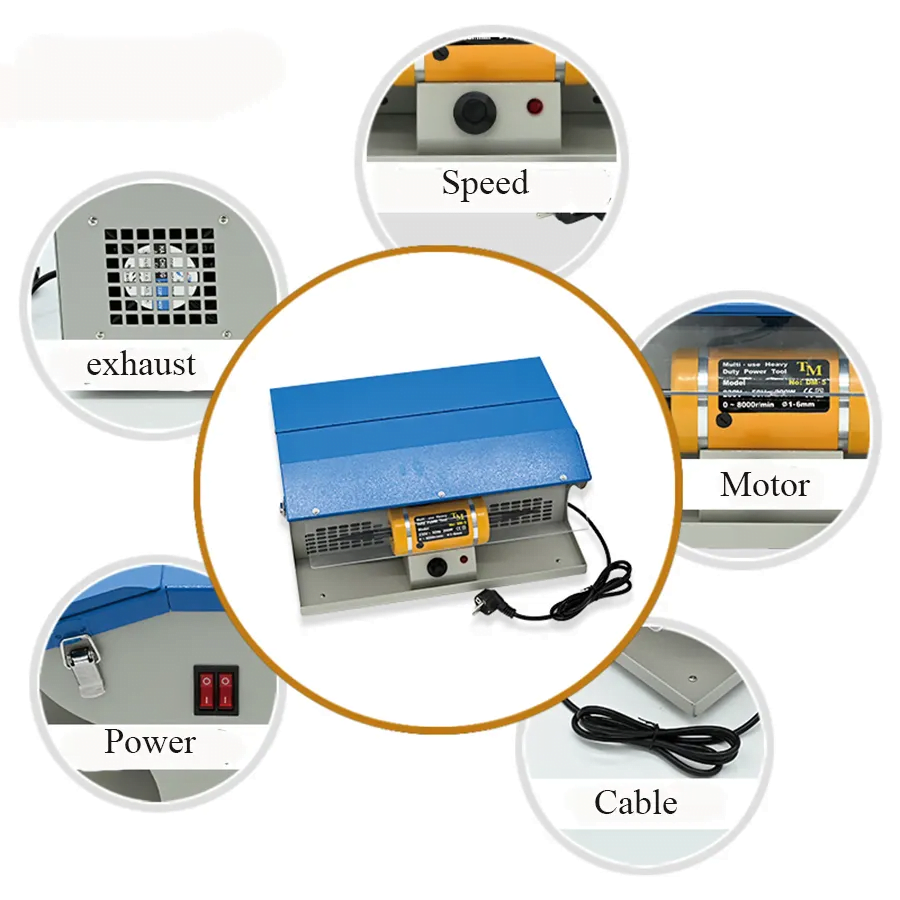

Polishing Machine with Dust Collector Metal Polishing Machine

Polishing Machine with Dust Collector Metal Polishing Machine

The Polishing Machine with Dust Collector TS 22 boasts a seamless integration of high-performance functionality and user-friendly design. Whether you are a seasoned professional or a budding enthusiast, this machine offers a seamless polishing experience, ensuring impeccable finishes on your metalwork.

Key features of the Polishing Machine with Dust Collector TS 22 include:

Advanced Dust Collection: Say goodbye to the hassle of post-polishing cleanup. Our integrated dust collector efficiently traps and manages dust particles, keeping your workspace clean and ensuring a healthier working environment.

Precision Control: Experience unparalleled precision with our state-of-the-art control system, allowing you to adjust speed and pressure to meet the unique requirements of each metal polishing task.

Durable Construction: Built to withstand the rigors of daily use, our Polishing Machine with Dust Collector TS 22 is crafted from robust materials, guaranteeing longevity and consistent performance over time.

User-Friendly Interface: With an intuitive interface and straightforward controls, this machine is designed to streamline your polishing process, reducing the learning curve and maximizing productivity.

At Casting Australia, we understand the importance of reliable and efficient casting equipment. That’s why our Polishing Machine with Dust Collector TS 22 is meticulously crafted to meet the highest industry standards, empowering you to elevate your metalwork to new levels of excellence.

Take your metal polishing endeavors to the next level with the Polishing Machine with Dust Collector TS 22. Browse our website to explore more top-quality casting equipment and experience the pinnacle of precision and efficiency in your craft.

Should you have any inquiries or require further assistance, please don’t hesitate to reach out to our dedicated support team. Elevate your metal polishing capabilities with Casting Australia today!

About Casting Australia

Established in March 2003, Casting Australia Technology Co., Ltd has evolved into a professional supplier of integrated lost wax casting solutions, including jewelry casting machines and related materials.

Our expertise lies in a focus on providing high-quality solutions to the casting industry.

Jewellery polishing tips

Here are some tips for jewellery polishing with a buffing machine:

- Choose the right buffing wheel.Buffing wheels come in a variety of materials, each with its own abrasive properties. For jewellery polishing, you will want to use a soft buffing wheel, such as a cotton or muslin wheel.

- Apply the correct polishing compound.Polishing compounds are available in a variety of grits, from coarse to fine. For jewellery polishing, you will want to start with a medium-grit compound and then work your way to a finer grit to achieve a high shine.

- Apply light pressure.When polishing jewellery, it is important to apply light pressure. Pressing too hard can damage your pieces.

- Keep the buffing wheel moving.Do not allow the buffing wheel to stay in one place for too long, as this can also damage your jewellery.

- Polish all sides of your jewellery.Be sure to polish all sides of your jewellery, including the back and any hidden areas.

Here is a step-by-step guide to jewellery polishing with a buffing machine:

- Secure your jewellery. Use a jeweller’s vice or a piece of tape to secure your jewellery. This will help to prevent your jewellery from slipping and being damaged. Chains can be wrapped around a suitable wooden dowel, on no account try to buff an unsecured chain, eyes have been lost attempting this

- Apply the polishing compound to the buffing wheel.Apply a small amount of polishing compound to the buffing wheel. You can use a brush or your fingers to apply the compound.

- Turn on the buffing machine and set the speed to medium.

- Hold the jewellery against the buffing wheel and apply light pressure.Move the jewellery around the buffing wheel, making sure to polish all sides of the piece.

- Continue polishing until the desired shine is achieved.

- Wipe away any excess polishing compound with a soft cloth.

Here are some additional tips for jewellery polishing with a buffing machine:

- Be careful not to overheat your jewellery, opal, peatl and amber will not stand it. If the jewellery becomes too hot, stop polishing and allow it to cool down.

- Avoid polishing jewellery with soft stones, as this can damage the stones.

- Clean your buffing wheels regularly to prevent the build-up of polishing compound.

- keep each buff in it’s own bag to avoid cross contamination of compounds

Polishing Machine with Dust Collector Metal Polishing Machine

Polishing Machine with Dust Collector Metal Polishing Machine